Every industry has a major role to play as we transition to a sustainable economy – especially transportation whether automobile, rail, air or sea. For aerospace, the process to build zero-emissions aircraft includes the steepest hurdles. Until now, sustainability has focused primarily on CO2 emissions during aircraft operation, and while this is an important area to address, attention also needs to be placed on the impact of material processing, manufacturing operations and how the aircraft will be maintained.

Significant developments already in operation

One way today’s OEMs are improving sustainability is by building greater efficiencies into the aircraft, which improves fuel economy and reduces fuel emissions. The Boeing 787 is a good example. The 787 is producing around 20 to 30 percent lower fuel burn on international flights. How? Boeing first improved overall aerodynamics which included modifying the wings. Boeing then incorporated lightweight structures (more composites) which also contributed to better overall fuel economies. Finally, Boeing transitioned to more electrically driven systems to improve the efficiency of the systems, and reducing the power extraction from the engines.

Another approach to sustainability is sustainable aviation fuel (SAF) adoption. SAF has been implemented by commercial airlines around the world. Some companies have made strides through their own corporate mandates, while others are following government regulations based on that company’s country of origin. In fact, most airlines around the world have committed to replacing ten percent of the jet fuel they consume with SAF by 2030.

Electrification of functionality throughout the aircraft is another contributor to a sustainable future. Boeing and Airbus have introduced a number of electrical systems (to replace mechanical or pneumatic systems) for improvements in performance, weight, efficiency and maintenance.

And let’s not forget the promise of the electric aircraft. Notable breakthroughs have occurred especially among regional carriers. The emergence of Heart Aerospace, Eviation and Bye Aerospace are testament to the validity behind the future of electric air travel. Of course, electric vertical take-off and landing (eVTOL) vehicles bring a new level of technology and excitement to the marketplace, and not just to the commercial side. In fact, the U.S. Air Force has already granted airworthiness approval for the Alia aircraft by Beta Technologies. They conducted the first airman flight earlier this year. We are expecting to see this segment continue to take off in the next two to three years.

In addition to current developments, the industry is making strides with “clean manufacturing”

With the current sustainability efforts already underway, companies are also shifting their mindset to focus on clean manufacturing. Clean manufacturing is an approach that allows OEMs to eliminate waste and lower their carbon footprint across the entire product development lifecycle.

One aspect to clean manufacturing is additive manufacturing. Today’s more robust additive manufacturing solutions include innovations in 3D printing. Using this type of approach allows for parts to be made in less time, perform better, weigh less and are easier to maintain. OEMs are able to get the parts they need when they need them — customized for operational performance and efficiency.

Clean manufacturing empowers the circular economy. It allows OEMs to add recycling requirements early in the product development stage. It’s building with a new intention to recycle/reuse old parts to lessen the demand for extracting natural resources or raw materials. It’s finding ways to lower the carbon footprint both inside the factory as well as throughout the broader ecosystem.

Addressing the zero-emissions aircraft

When we talk about decarbonizing the aerospace industry viable options include SAF and clean manufacturing. But what about building a true, zero-emissions aircraft? Structures will have to adhere to an evolving set of rules. Simulation, propulsion, design characteristics, aerodynamics, structural analysis all need to come together and be analyzed in a meaningful and insightful manner.

At this time there are two propulsion options for the zero-emissions aircraft: electric and hydrogen. The electric aircraft has made significant progress, but with current power densities, it has a limited cruising range. We’ll likely see electric aircraft for short hauls and medium-range flights. That leaves the long-range flights to hydrogen.

Hydrogen shows promise and could be the future of air travel, but it has its own technological challenges. Will it be used as a combustible — fuel for a modified gas turbine engine? Or as a fuel-cell battery which provides electricity for propulsion? Some in the industry believe hydrogen can be used today as a combustible with adjustments to the engine and combustion chamber. The real challenge with hydrogen is dealing with cryogenic temperatures and/or high pressures for storage. Hydrogen burns hot, and as a result, produces nitrogen oxide (NOx) as a byproduct. OEMs will need to design a “cooler” combustion process that reduces or eliminates NOx.

The bottom line: whatever the shape and propulsion type of the zero-emissions aircraft, to be successful OEMs will need a highly digitalized design and manufacturing environment where all data is shared, processes are automated and there’s open collaboration across all domains and design disciplines.

Building a digital enterprise – complexity becomes a competitive advantage

The best way to address the challenges around sustainability and the zero-emissions aircraft is to transition to a digital enterprise. A&D companies, their partners and entire supply chain need to adopt the digital twin and digital thread. A comprehensive digital twin enables teams to better predict the effects of hydrogen (in storage) by analyzing, simulating and verifying before physical production begins. Teams gain valuable insight by generating thousands of iterations on how to best design and build liquid hydrogen storage tanks, for example.

While a digital twin can be set up for just about anything in the engineering or manufacturing disciplines, if it’s not connected or integrated to other phases of product lifecycle development, teams will not realize the twin’s full potential. Teams need digital threads which seamlessly connect the comprehensive digital twin to all phases of the development and production for the continuous exchange of data – the automation of data – up and down the product development lifecycle.

A closer look at the MBSE digital thread

Aerospace companies looking to implement more sustainable products and processes are moving towards model-based system engineering (MBSE). MBSE is growing within the A&D industry because it’s a more disciplined approach to systems engineering. It brings a new level of integration and efficiency to complex systems and processes across the many multi-domain challenges aircraft manufacturers employ today. When companies move to a MBSE approach they collaborate more easily across domains and throughout their supply chain.

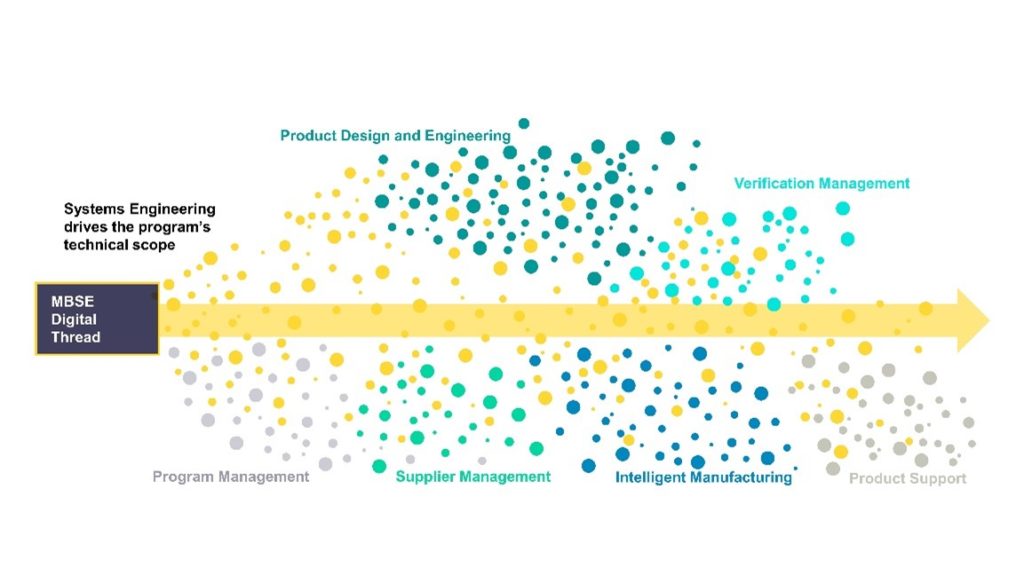

The MBSE approach is more than functional or logical modeling. It’s actually about building a digital thread (MBSE digital thread) that serves as the “digital backbone” uniting engineering, manufacturing, supply chain, and program management activities (Figure 1).

Implementing the MBSE digital thread enables teams to confidently explore and simulate alternative designs. Continuous verification comes from the digital nature of the solution – traceability of the design. Since the entire design process is defined with a comprehensive digital twin, every design change and update is tracked against the product definitions for the project. Product requirements can be easily tracked throughout the product lifecycle. Using MBSE for the circular economy or for clean manufacturing allows recycle requirements to be built into the early concepting stages and tracked throughout to verify that the requirements have been met.

Additive manufacturing plays a key role

In many respects, the more innovative zero emissions aircraft will require platforms that are custom configured which means additive manufacturing will play a key role. Additive manufacturing not only revolutionizes how teams build parts and assemblies, but dramatically changes how to design parts. Recognizing this, Siemens has paved the way to the future of more sustainable products and processes by investing in design and manufacturing technologies that maximize the benefits of additive manufacturing by automating the entire manufacturing process.

Realizing the zero-emissions aircraft – together

Siemens is at the forefront of helping A&D companies of all sizes master complexity and build more sustainable products. By leveraging digital technologies — the comprehensive digital twin and digital thread — aerospace companies can transform how they operate, collaborate and share information across the product development lifecycle. Customers are also discovering the powerful capabilities behind our Xcelerator offering, a comprehensive, integrated portfolio of software, services and an application development platform. Xcelerator serves as the catalyst for the digital transformation.

Whether it’s maximizing the potential behind SAF, introducing the concepts and technologies behind smart manufacturing, or using the digital enterprise to build the future zero-emissions aircraft — our prime directive is to help A&D customers achieve their strategic objectives as they incorporate sustainability into all facets of operation.