INDIANAPOLIS—Rolls-Royce is in the last few months of testing its F130-200 engines before a critical design review of the powerplants, which will equip the re-engined and upgraded B-52J, a company official said.

“We’re about one-third through” engine runs with F130-200 Nos. 1 and 2, F130 program manager Scott Ames said in a briefing at the company’s Indianapolis facilities where the powerplants will be assembled. The F130-200 critical design review is expected in January 2024, and Ames said Rolls-Royce sees no threat to passing the review.

Boeing, which built the B-52, is the overall integrator for the re-engining and upgrades, such as the radar, that will turn the Air Force’s 75 B-52Hs into B-52Js. Boeing and Rolls-Royce provided travel, lodging, and meals for reporters visiting the companies’ B-52 upgrade facilities.

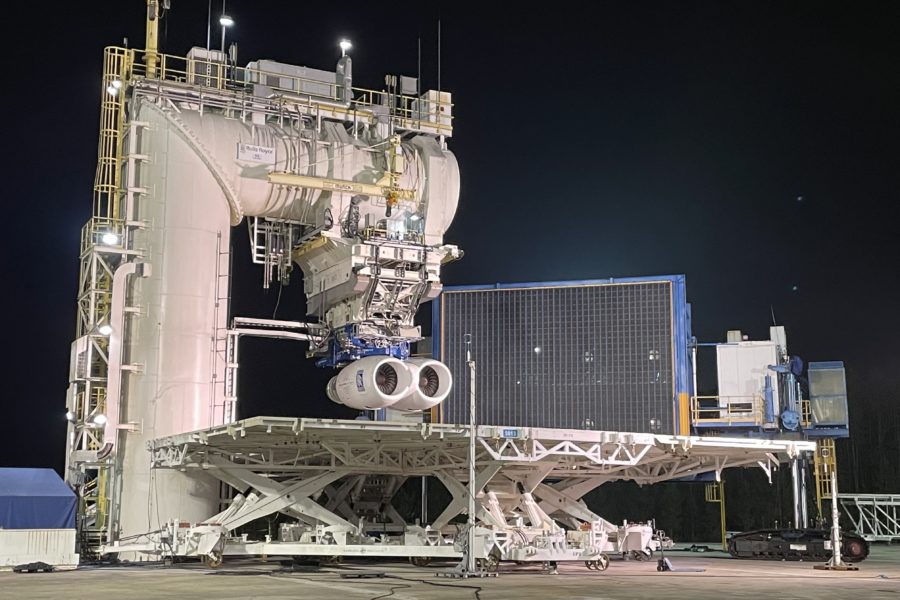

The tests of the Rolls-Royce engines mark the first time two engines have been operated simultaneously on the same test stand, Ames said. The B-52 is unique in having two engines each in four pods under its wings, for a total of eight engines per aircraft.

The engines are being tested at NASA’s Stennis Space Center in Mississippi on a specialized test stand that allows a complete, two-engine pod to be operated under a variety of conditions. A giant wind fan tests the engines in simulated crosswinds of up to 50 knots from various directions, and a platform on a scissor lift in front of the engines can simulate operations at various heights above a runway.

Ames said Rolls-Royce is now on its seventh iteration of the pod design, in search of the best configuration under most conditions—as well as looking for unexpected interactions between the engines. So far, there have been no harmonic issues between the powerplants, nor has there been unexpected ingestion of gases from one to the other, Ames said.

What’s being explored is “how does the air coming into the engine nacelles … behave?” Ames said. “You don’t really see a lot of dual-pod configurations like this. So we want to make sure all our modeling matches … the physics of the situation.”

Three months into the tests with three more to go, Ames said “we’ve been able to operate both engines up to full power and all of the test data we’ve gotten back has been in line with what our models predicted. … It’s proven that we’ve got it right. And by the way, it matches what Boeing predicted as well. So that’s good, but it’s always good to do a physical test to back that up.”

To that point, Ames said, both Rolls-Royce and Boeing are “happy” with this latest pod design but are testing to “make double sure” it’s the right one.

After that, “we will run [a] similar test to this in a couple of years” on the final version, with all the equipment and auxiliary systems the aircraft and pod will have, he noted.

“We wanted to get the front end right now,” Ames said. “It was something we proposed to de-risk the overall program, because if you find that you’ve got to make some big change you want to know now and not three years from now.”

The F130-200 is a derivative of Rolls-Royce’s commercial BR725 engine, and will be manufactured from parts sourced from the same suppliers. It differs from the commercial version in the digital engine controls and connection of hydraulic and fuel lines, all of which are unique to the B-52 application, Ames said. The F130-200 factory will be patterned on the main BR725 production line in Germany but with improvements geared to the F130-200’s unique features.

Ames also noted the F130-200s are not “handed,” meaning they are not hard-wired to be on the left or right side of the nacelle, unlike the TF-33 engines now flying on the B-52. This will give the Air Force improved flexibility both at home and on deployments, he said.

With the TF33, due to its left- or right-side orientation, “you have to take extra spares on deployments,” he said. “With our engine, you don’t have to worry about that. So with the kit, you can change it from a left hand or right hand in about 90 minutes.”

Rolls-Royce tested that timeline with two veteran mechanics who did not have specific experience with the F130.

“We gave them a set of instructions and the kit of parts and said ‘Go convert this from one to the other,’” Ames said. “We videotaped it, and provided that to the Air Force. In about 90 minutes they were able to convert it over. We think it gives the Air Force a ton of flexibility.”