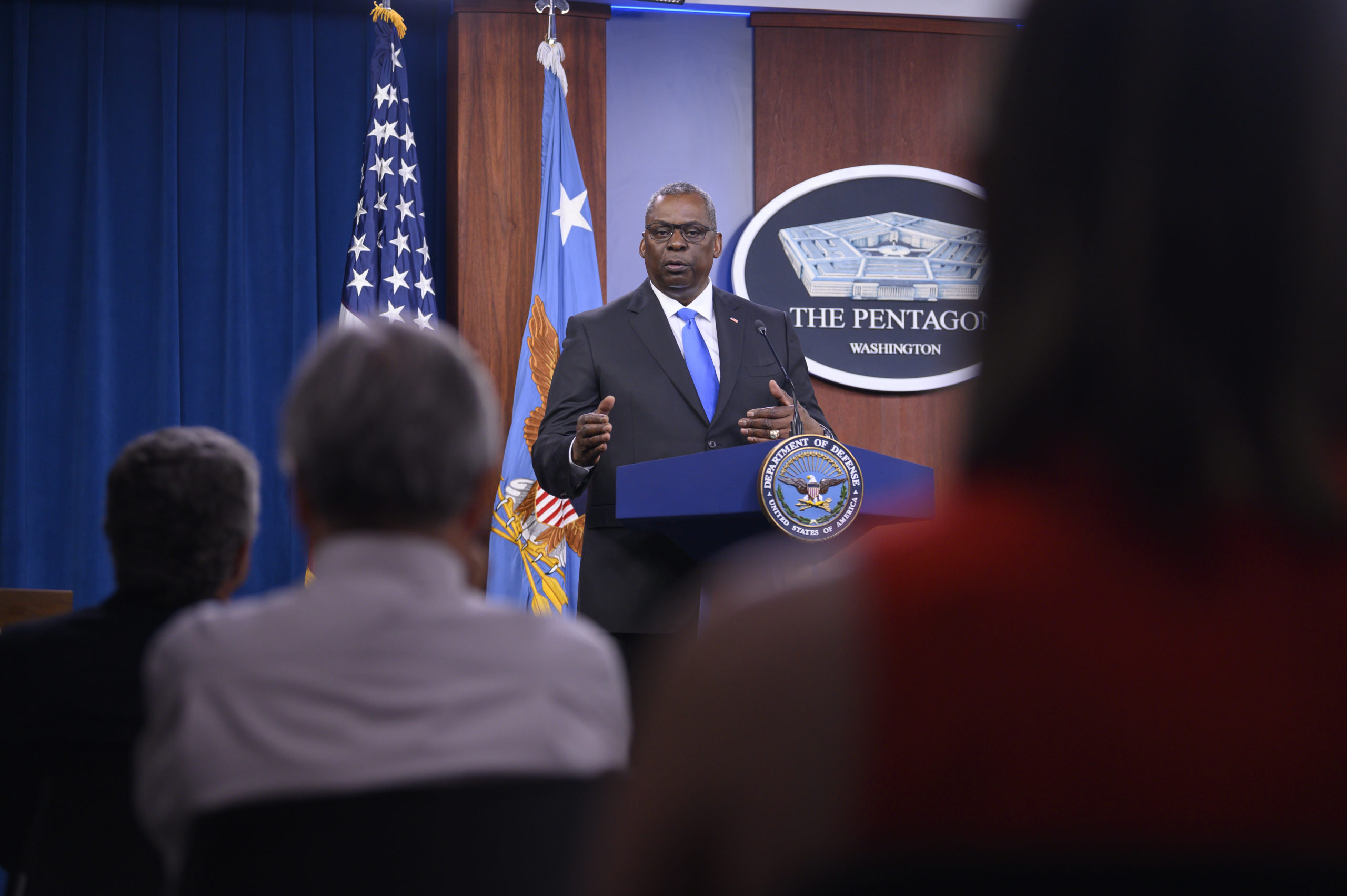

Defense Secretary Lloyd J. Austin III chaired a China-focused military briefing Oct. 27, part of a biweekly series of briefings with senior military commanders about China’s growing threat in the wake of an orbital hypersonic weapon test that elicited public worries from the Chairman of the Joint Chiefs.

A flurry of attention about the possibility that China tested a nuclear-capable hypersonic weapon in August was confirmed by Chairman of the Joint Chiefs of Staff Army Gen. Mark A. Milley in a Bloomberg TV interview released Oct. 27.

“What we saw was a very significant event of a test of a hypersonic weapon system. And it is very concerning,” said Milley. “I don’t know if it’s quite a Sputnik moment, but I think it’s very close to that. It has all of our attention.”

Pentagon Press Secretary John F. Kirby declined to comment on the Chinese test first reported by Financial Times, but he confirmed that Austin has maintained regular China-oriented briefings after a DOD China Task Force stood down in June.

“I literally just came from the Secretary’s latest China brief,” Kirby said during an Oct. 27 Pentagon briefing. “One of the things he tasked himself with at the end of the task force was personal leadership over a regularly scheduled coordination and discussion session with the senior leadership here at the department, including the service Chiefs and the service Secretaries, as well as appropriate combatant commanders.”

Austin defined China as the department’s “pacing challenge” during his nomination hearing Jan. 19 and has repeatedly warned of China’s aggressive behavior and rapid military technological advances.

Kirby said no one Chinese technology is the most concerning to the Secretary.

“There’s a suite of issues with respect to China from the security perspective,” he said. “Taken together, all those things are reason for concern.”

The department’s work under Austin began with the task force that interviewed hundreds of experts and reviewed thousands of pages of policies, analysis, and intelligence. The task force, led by Assistant Secretary of Defense for Indo-Pacific Security Affairs Dr. Ely S. Ratner prior to his confirmation, is now informing every aspect of the U.S. security approach to China.

That includes operational concepts, the DOD budget, programs, priorities, training, and exercises, and it will be a factor in the global posture review and upcoming National Defense Strategy.

“A free Indo-Pacific remains a key national security goal of the United States,” Kirby said.

Kirby made clear the U.S. is not there yet when asked about America’s own hypersonic capabilities and defenses against an adversary’s use of a hypersonic weapon.

“It’s in the budget,” he said. “Our own pursuit of hypersonic capabilities is real, it’s tangible, and we are absolutely working towards being able to develop that capability.”

The Air Force has conducted a series of hypersonics tests in recent months, although some have failed.

“This is not a technology that is alien to us, that we haven’t been thinking about for a while,” Kirby said. “I would argue that it’s not just our own pursuit of the sort of technology, but our mindfulness that we have defensive capabilities that we have to continue to hone and to improve.”