As the Air Force Research Laboratory is studying the space environment in space, it’s also building a new device to simulate the space environment in a lab.

Both activities could help the Space Force predict and track the well being of satellites.

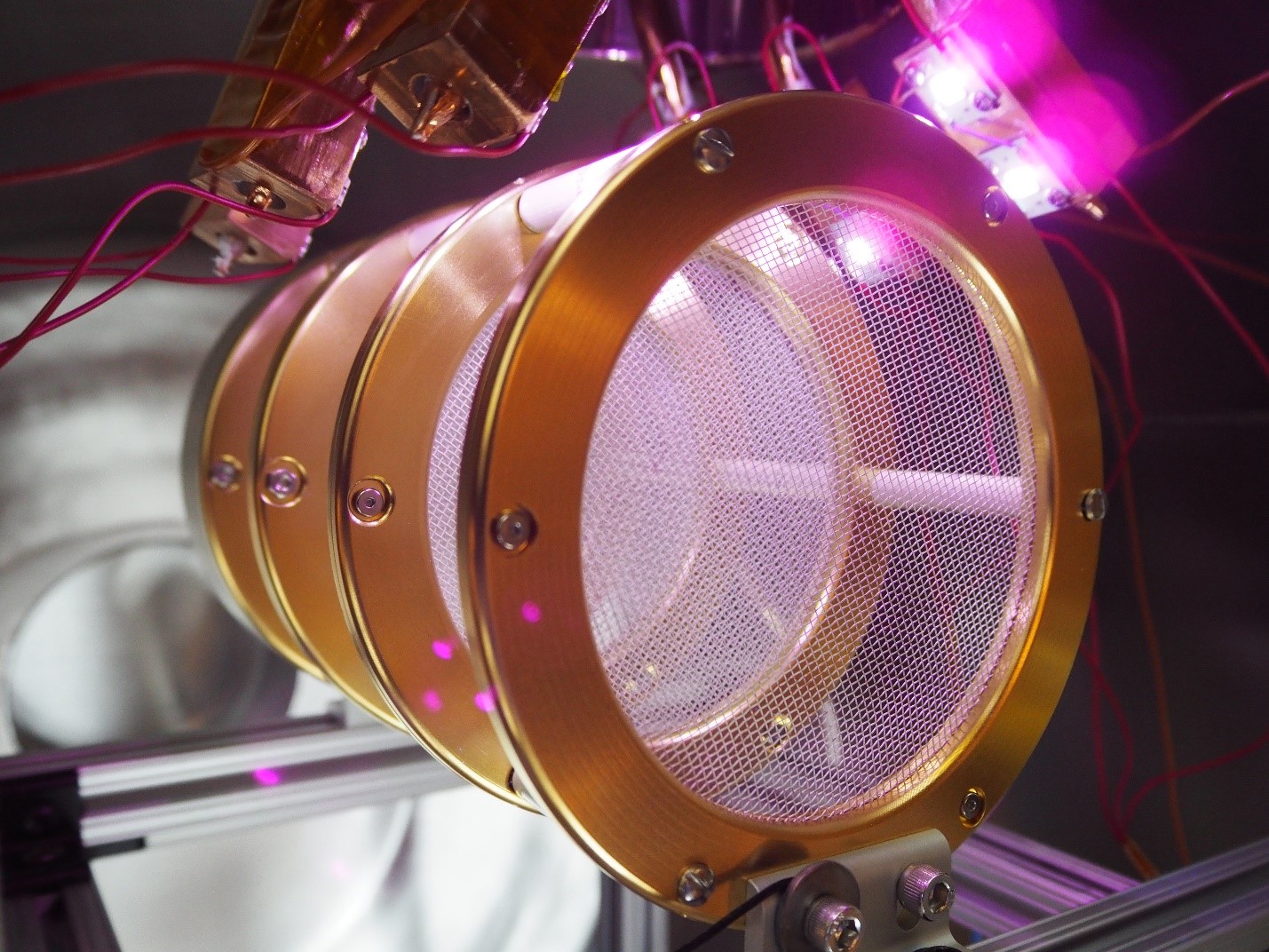

AFRL’s Space Vehicles Directorate at Kirtland Air Force Base, N.M., is building a “multi-energy electron source” that emits radiation in dozens of different wavelengths all at once.

A postdoctoral scientist with the directorate, Miles Bengtson, invented the electron device while he was a graduate student at the University of Colorado Boulder. The directorate’s Spacecraft Charging and Instrument Calibration Lab brought Bengtson onboard to advance the electron device to operational status, according to an AFRL release.

Bombardment by the likes of electron radiation can degrade a satellite’s performance.

“The problem” with how labs conventionally recreate such radiation for experiments is that the electron sources “are monoenergetic only,” Bengtson said in the release. “They only emit electrons at one energy,” or wavelength, “whereas the space environment contains electrons distributed across all energies, simultaneously.”

The availability of the new testing environment could translate to faster adoption of new construction materials and better experiments to study materials, electronic charging, and other aspects of spacecraft affected by the space environment.

Physicist Ryan Hoffmann, who leads the Spacecraft Charging and Instrument Calibration Lab, said in the release that so far, two prototypes of the new electron device “have demonstrated basic functionality” and that an advanced prototype being built “will be very close to a fully operational model.”

Studying Space From the Ground

Meanwhile, the 72-acre Skywave Technology Laboratory, located on a remote parcel at Kirtland, is getting a better grip on the space environment itself.

The lab’s two antenna setups include a transmission tower with a measuring device; and a long array of poles amounting to a high frequency radar. Both setups beam electromagnetic transmissions into the plasma of Earth’s ionosphere, “propagating” the beams—refracting and scattering them—off the subatomic particles comprising the plasma.

The “state of the plasma,” such as its density and any disturbances, can interfere with space communications, said Todd Parris, chief of the Space Vehicles Directorate’s Geospace Environment Impacts and Application Branch, in an emailed reply to a query by Air Force Magazine.

Officially opened in April, the Skywave lab “will focus mainly on the radio impacts to space services,” Parris said.

Parris confirmed that knowledge of the space environment could help the Space Force distinguish between an electronic attack on a satellite and the environment’s natural effects. Understanding environmental electromagnetic interference “is usually the first step in attributing the effects on a spacecraft—ruling in, or ruling out, the space environment,” he said.