Northrop Grumman opened its new hypersonic propulsion factory in Elkton, Md., August 3, where it will build scramjet engines for the Air Force’s Hypersonic Attack Cruise Missile as well as ramjets, warheads, and other components for future hypersonic systems.

The 60,000-square-foot “Hypersonic Capability Center” employs just over 50 people now in digital and production work, but Northrop designed the facility to be “rapidly expandable” and reconfigurable to increase manufacturing capacity for HACM and accommodate other projects. Northrop’s aim: to build hypersonic elements “at scale,” company officials said.

Northrop provides the air-breathing scramjet propulsion system and warheads for HACM to its prime contractor, Raytheon. The team won a cost-plus development contract for the weapon in September, 2022. The initial asset is expected circa 2027.

Air Force Secretary Frank Kendall said USAF switched its “focus” to HACM as its primary hypersonics effort after the AGM-183 Air-Launched Rapid Response Weapon (ARRW) failed to impress in early testing. HACM’s smaller size and longer range—thanks to its air-breathing scramjet propulsion—makes it more attractive for the Air Force, Kendall and Andrew Hunter, his chief acquisition executive, have said. The smaller weapon can be carried by fighers, as well as big bombers like the B-52.

The HACM is based on development work done led by the Air Force and the Defense Advanced Research Projects Agency, building on the Hypersonic Air-breathing Weapon Concept (HAWC) and work Raytheon did in a joint program with Australia called SCIFiRE, for Southern Cross Integrated Flight Research Experiments. Initial HACM flight tests are expected to be conducted in Australia.

Raytheon’s version of HAWC flew successfully in September 2021 and July 2022.

The HACM is “obviously a key and critical program for us,” said Chris Haynes, Northop director of business development for missiles.

The HCC, he said, “is going to be a combination of modern equipment, as well as leveraging digital engineering techniques…We’re really trying to drive” having engineers work “side by side with operations, fully integrated on the floor. So as we’re making design decisions, we understand the implications of those decisions as it relates to…delivering weapons that are reliable, affordable and at scale,” Haynes said.

The design of future weapons will have to take manufacturing into account at the outset, in order to hit the price points government is willing to pay, he said.

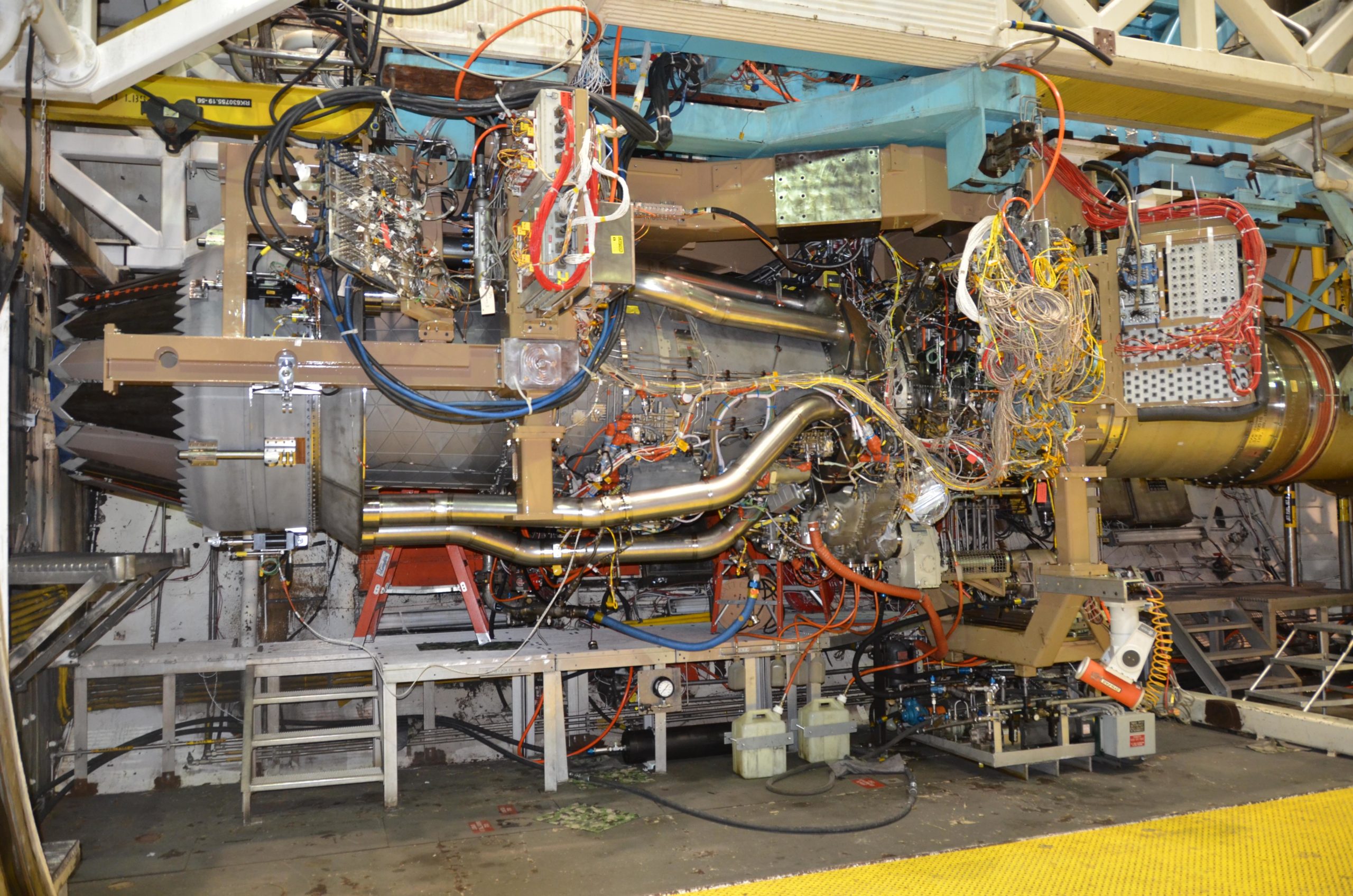

The facility is “purpose-built…for design, development and manufacturing of hypersonic air breathing propulsion, all under one roof,” he said. There is no capability to build hypersonic propulsion systems “at scale in the industry today,” Haynes said. The “foundational elements” of such a capability don’t exist at the scale that they do for solid rocket motors, he said.

Ground was broken on the HCC in 2021. The new facility consolidates some of Northrop’s engineering talent from its Ronkonkoma, N.Y., and Palm Beach Gardens, Fla., facilities to concentrate the company’s critical mass of hypersonic expertise.

Haynes noted more than five active hypersonic programs among the Army, Navy, and Air Force and said the company expects the number of programs and the number of deliverables to increase substantially.

“As an industry leader on the components and missile side of things, we’re obviously well positioned to play a critical role in developing these new systems from the propulsion perspective, from a fusing perspective; warheads, advanced materials; they’re all critical to delivering this capability,” he said. The underlying goal is “affordable mass.”

Northrop’s provides HACM’s scramjet, solid rocket motors, and fusing capabilities, while Raytheon provides control actuation, forward section electronics, and endgame sensors, Haynes said. The weapon will be delivered out of Raytheon’s facilities in Tucson, Ariz.

Haynes said the two companies “fully integrated” their efforts through digital thread and integrated networks across the whole of the HACM effort.

“We are able…to collaborate [in] real time with our partners, with our supply chain, to be able to make design decisions [and] make manufacturing decisions,” Haynes said.

Haynes said Northrop also will build hypersonic engines for “future air-breathing systems,” but did not elaborate. Elkton will also produce the third stage rocket motor for the Navy’s Standard Missile, another Raytheon product.

Jones also said that Northrop is partnering with “local high schools and universities and colleges to create programs dedicated towards building a trained skill set within the community. So we have a workforce of the future, essentially.” Elkton is about 8 miles from the University of Delaware, just over the state line in Newark, Del.