As the Pentagon and other government agencies become more reliant on information provided by commercial satellites, the line between military and civilian targets in space will become increasingly blurred in future conflicts, three former Air Force space experts-turned-commercial space executives said during a panel discussion hosted by the Hudson Institute on July 26.

As a sign of things to come, the executives pointed to the role that communications and imaging satellites owned by SpaceX and Maxar Technologies have played in Ukraine’s defense against Russia’s invasion. Much of the U.S. military’s current communication system also runs through commercial satellite systems, the panelists said.

“I think we’re not spending enough time talking about the coupling between the commercial operators and the [Department of Defense] in a conflict that extends into space,” said Even Rogers, former Air Force space operator and CEO of the space technology company True Anomaly.

“Commercial operators become targets when they support the DOD,” Rogers added. “In fact, I suspect that there are some incentives that would cause commercial operators to be targeted first as a strategic off-ramp in a broader conflict, because it is a gray zone, there is uncertainty about whether the United States intends to defend and protect … commercial providers.”

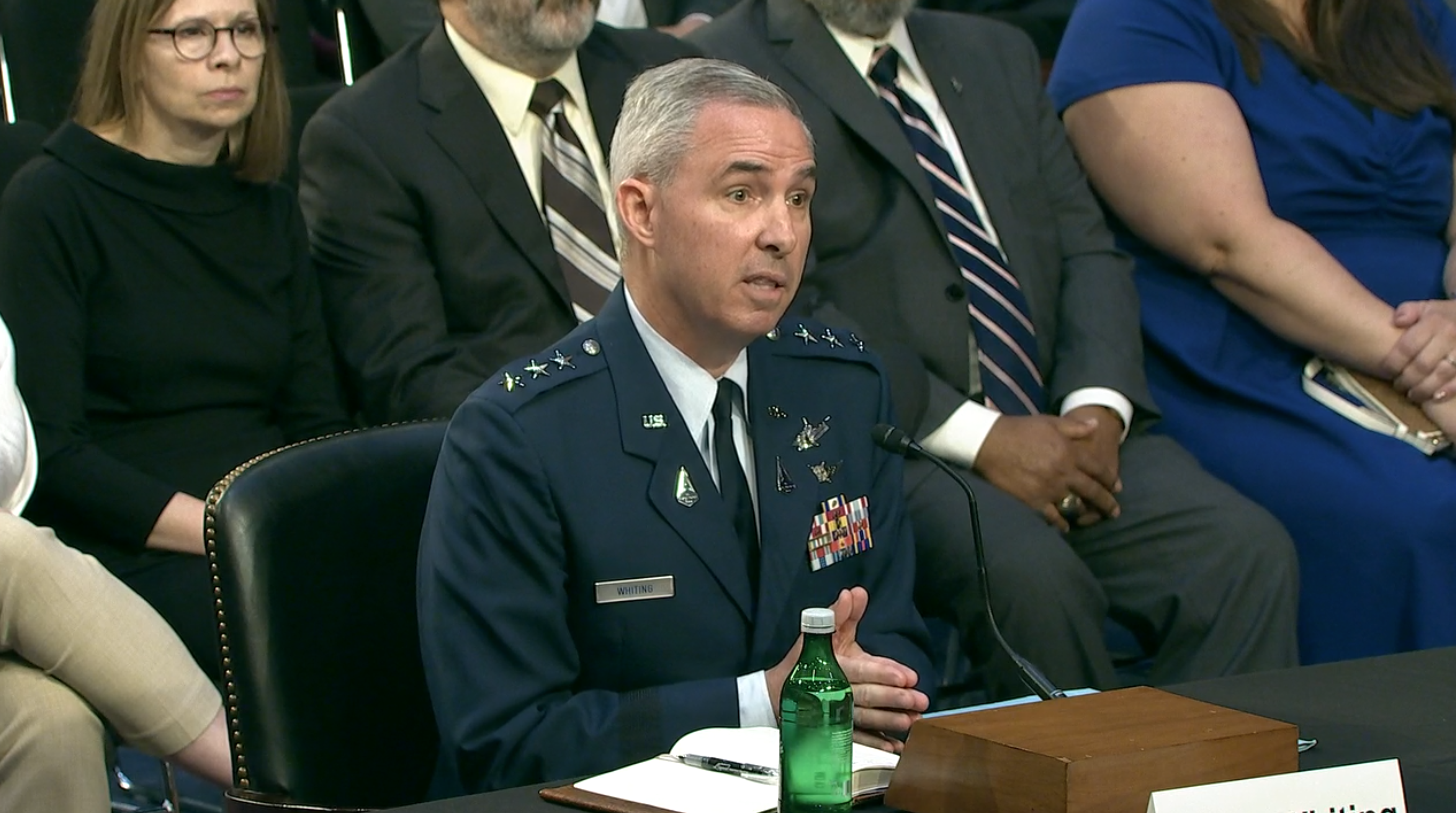

Indeed, the same day of the Hudson Institute panel, the nominee for the next leader of U.S. Space Command, Lt. Gen. Stephen N. Whiting, told the Senate Armed Services Committee that the military ought to work more closely with industry to accelerate fielding new technologies.

Whiting’s testimony also seemed to confirm the “gray zone” status of commercial space assets. When Sen. Jeanne Shaheen (D-N.H.) asked if an attack on U.S. commercial satellites constitutes an act of war, the general demurred, calling it a policy question and stating SPACECOM’s job is to provide decision-makers options for defending commercial space capabilities.

“We must continue to partner with those companies, so that they look to build resilience into their systems,” he said, so that, “if we do need to actively defend them, we have the communication avenues open to be able to do so.”

Executives at the Hudson event made similar calls for close cooperation. The way to deter gray zone aggression and preserve the capabilities that the government relies on is to establish “rules of the road” for what constitutes acceptable behavior in space, said retired Air Force Col. Dean Bellamy, now executive vice president of national security space for Redwire.

Specific examples of behavior that could be normalized include rendezvous and proximity operations, where two spacecraft have to draw up close to one another in orbit, said Jason Kim, a senior policy analyst at the National Oceanic and Atmospheric Administration.

Commercial operators could hold a certain distance and broadcast what they are up to in order to promote transparency during such an operation, Kim suggested. But transparency requires constant awareness of events in orbit and an established process for dealing with bad behavior. Rogers pointed out that a similar system already exists on Earth in the form of air-to-air intercepts.

“Very rarely do air-to-air intercepts result in any sort of catastrophic activity,” he said. “There’s ways that I think industry partners and the government can work together to establish those procedures, demonstrate those procedures, and adhere to them.”

Rogers’ company, True Anomaly, produces Jackal, an autonomous orbital vehicle built to carry out rendezvous and proximity operations. Another panelist and former Air Force officer, Chris Shank, is vice president of defense and space programs at Maxar, whose imagery-producing satellites can track activity both on Earth and in orbit.

Both military leaders such as Whiting and civilian government officials like Kim say stability in space, secured with industry’s help, benefits everyone.

“Space sustainability in general is a huge concern for all of us, not just for national security but for commercial and civil space,” Kim said. “It’s in all of our collective interest to maintain the sustainability of space and to not allow a war to escalate into space.”