The Space Development Agency isn’t slowing down anytime soon.

On Oct. 2, the organization released a notice to industry outlining its plans for an acquisition push in 2025. The SDA is seeking to procure around 200 satellites from different solicitations for Tranche 3 of its low-Earth orbit megaconstellation.

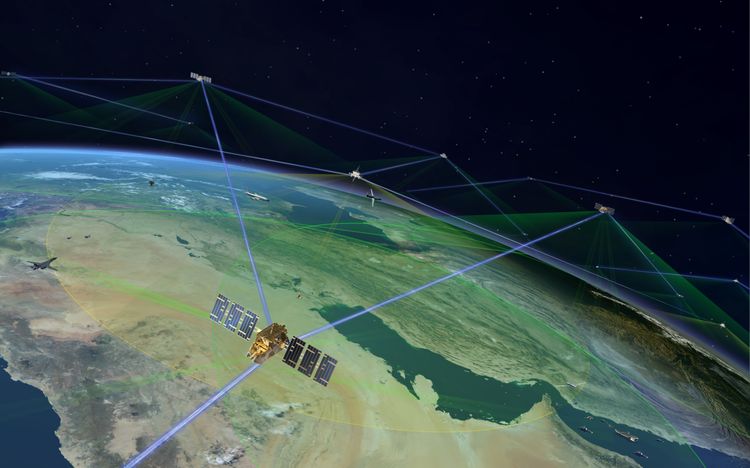

The Proliferated Warfighter Space Architecture, as SDA calls their constellation, is envisioned as the “backbone” for the Pentagon’s joint all-domain command and control (JADC2) efforts, providing both data transport and missile warning/tracking satellites that can connect sensors and shooters around the globe.

In the first quarter of fiscal 2025—the last three months of calendar 2024—SDA plans to release solicitations for integration work on Tranche 3. General Dynamics has already received contracts worth up to $887 million for ground operations and integration for Tranches 1 and 2.

After that will come a series of draft and final solicitations for the satellites themselves. Last month at a conference hosted by Defense News, SDA director Derek Tournear said the whole of Tranche 3 will likely include around 140 Transport satellites and 54 Tracking birds, though those figures are not final.

In its announcement, SDA confirmed that it will continue to take a three-pronged approach to its Transport satellites, with different groups having different levels of capabilities. While the Tranche 2 Transport Layer had Alpha, Beta, and Gamma segments, Tranche 3 will have Upsilon, Sigma, and Lambda groups.

- T3TL Upsilon: A draft solicitation will come out early in the second fiscal quarter of 2025—the first few months of the calendar year—followed by a final one early in the third fiscal quarter, around April or May. Up to two vendors will be selected.

- T3TL Sigma: A draft solicitation will come out late in the second fiscal quarter of 2025—the first three months of the calendar year—followed by a final one late in the third fiscal quarter, around May or June. Up to two vendors will be selected.

- T3TL Lambda: A draft solicitation will come out late in the third quarter of fiscal 2025—around May or June—followed by a final one toward the end of the fiscal year, in August or September. Up to two vendors will be selected.

A draft solicitation for the Tranche 3 Tracking Layer is expected early in the second quarter of fiscal 2025—the first few months of the calendar year—and a final one will come late in the third quarter—around May or June.

“Additionally, SDA is contemplating a PWSA Enterprise Ground effort which will be competed but details, including timeline, are still under development. SDA intends to update this announcement with that information when available and appropriate,” the announcement notes.

Details including a description of the overall architecture and payload configurations for each segment are not being released publicly as “controlled unclassified information,” but Tournear did offer some details during the Defense News Conference.

Tranche 3, scheduled to start launching in late 2028, will mark a turning point for the PWSA. After the “demonstration” Tranche 0, Tranche 1 is meant to provide an initial operational capability and Tranche 2 will add more spacecraft on orbit to provide global persistent coverage. Tranche 3 will be the first to replace earlier PWSA satellites with refreshed, improved capabilities—a model SDA officials refer to as “spiral development.”

“Keep in mind, all of our satellites have five year design lives,” Tournear said. “And so the idea is, at the end of Tranche 3, we will start and have already decommissioned our Tranche 1 satellites. At the beginning of Tranche 3, Tranche 1 will be up and operational. But towards the end of Tranche 3 … our Tranche 1 satellites are going to be decommissioned.”

The requirements for Tranche 3 were approved ahead of schedule by the SDA’s Warfighter Council in late August, Tournear noted, giving the agency more time to meet its launch deadlines.

“The Tranche 3 satellites have to do a few things,” Tournear added. “They have to replenish the capabilities the Tranche 1 was providing. Primarily on transport, that means you have to maintain that Link 16 constellation. And then add additional capabilities. The new capabilities in Tranche 3 will be advances in things like phased arrays to allow us to go down to more users at a time, primarily that’ll be in our S-band terminals, to be able to go down to more what we call the tactical SATCOM, which is a special user community that’s using those S-band signals. And then advances in in Link 16 encryption are going to be fielded.”

For the Tracking Layer satellites, Tournear said Tranche 3 will push the constellation forward toward missile defense—going beyond sensing launches and tracking flight patterns toward providing all the data needed to deploy interceptors against missiles. Some missile defense satellites were included in the procurement for Tranche 1 and Tranche 2, but Tournear could not say exactly how many of the 54 satellites in the Tranche 3 Tracking Layer would be capable of that.