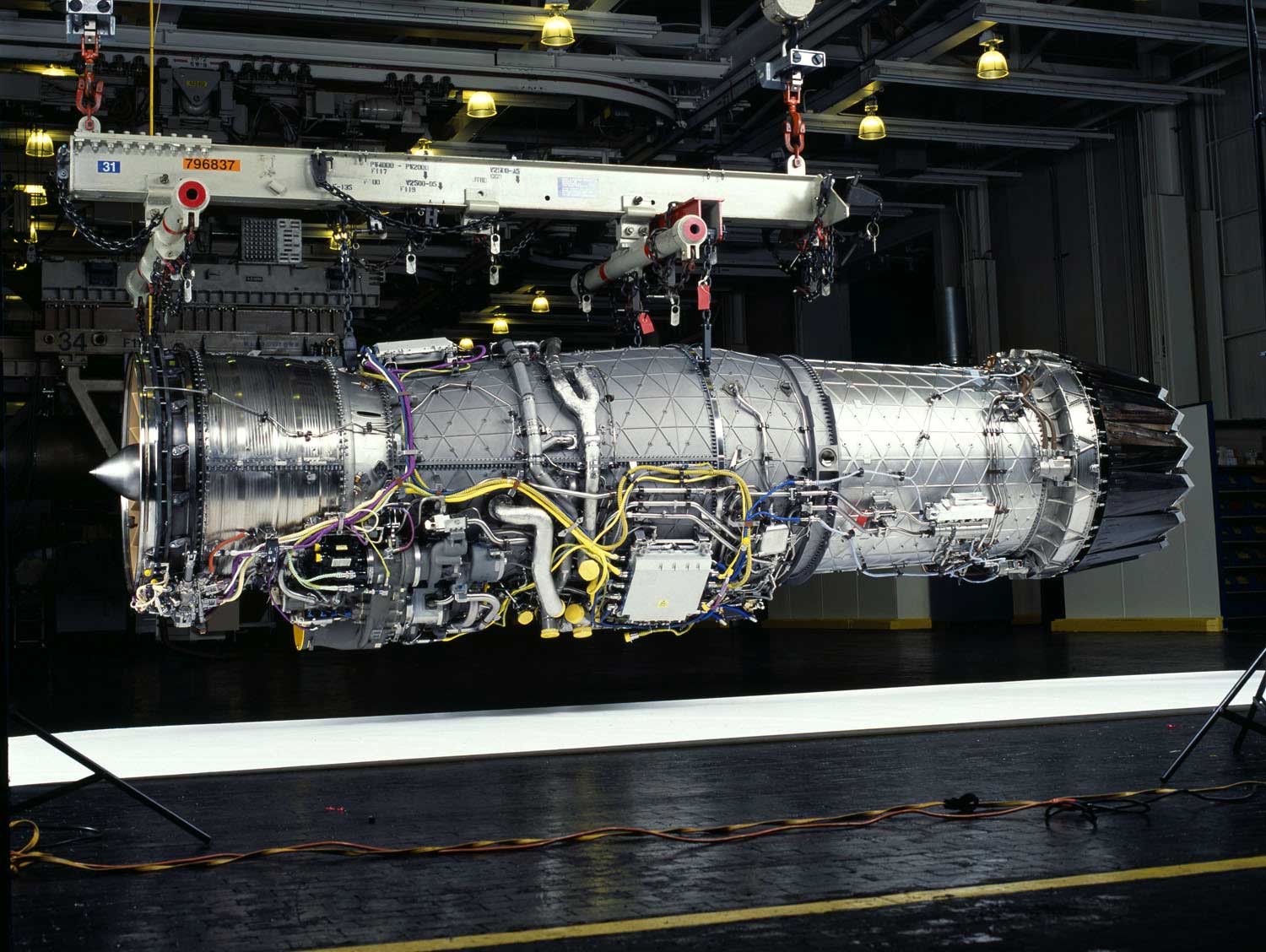

No F135 fighter engines are yet known to have parts made from contaminated powdered metal—a situation affecting much of Pratt & Whitney’s commercial engine fleet—but if detected, they’ll be replaced at depot and shouldn’t have a major impact on operations, a F-35 Joint Program Office spokesperson told Air & Space Forces Magazine.

The JPO concurs with comments from RTX’s chief operating officer Chris Calio, who said on the company’s third quarter earnings call Oct. 24 that “the Joint Program Office is reviewing our fleet management plan recommendation, which we believe will have limited, if any, operational impact on the customer. We continue to evaluate the balance of the Pratt fleet containing powdered metal, and expect any fleet management plan updates, if needed, to have limited impact.”

RTX is the parent company for Raytheon Technologies, Collins Aerospace, and Pratt & Whitney.

The JPO agreed, saying through a spokesperson that “the issue will have little to no impact on the fleet.”

RTX officials said they are working through inspections and groundings affecting many of their airline and freight customers, who RTX said will be compensated for the downtime. It will be “expensive,” RTX president and CEO Greg Hayes said on the call. On the previous quarterly call, he said RTX will “make our customers whole” for the downtime.

The issue goes back to a quality escape in 2015, when a Pratt supplier provided powdered nickel with fine contamination. The quality issue was discovered after an in-flight failure in 2018, and in subsequent tests, Pratt found that the parts made from the powder have less durability and could fail. This has caused the company to order inspections and accelerate the schedule for off-wing maintenance. Pratt is replacing parts found to have the contaminated metal with new ones and expects to get through the process of replacing all affected units by the end of 2025.

The JPO said it has been aware of the contaminated nickel powder issue since 2021, “and it is a low-risk issue for the F135 because the component will be inspected, and replaced if needed, well before the issue would potentially impact the engine,” a spokesperson said.

Parts potentially affected by the quality issue include high-pressure discs in the F135, sources said, but the JPO said none have been detected so far.

“At this time, no F135 components inspected have exhibited contamination,” the spokesperson said. The components potentially affected are being inspected when the engines come in for scheduled depot maintenance. If any are found to be contaminated, they’ll be replaced at depot, the spokesperson said.

The problem most profoundly affects the PW1100 engine that powers Airbus A320 airliners. Pratt started making parts from new material two years ago, and has reorganized its production facilities to make replacement parts at an accelerated rate.