Air Forces Central has unveiled a colorful new patch to acknowledge the significant role U.S. allies and partners play in military operations in the Middle East.

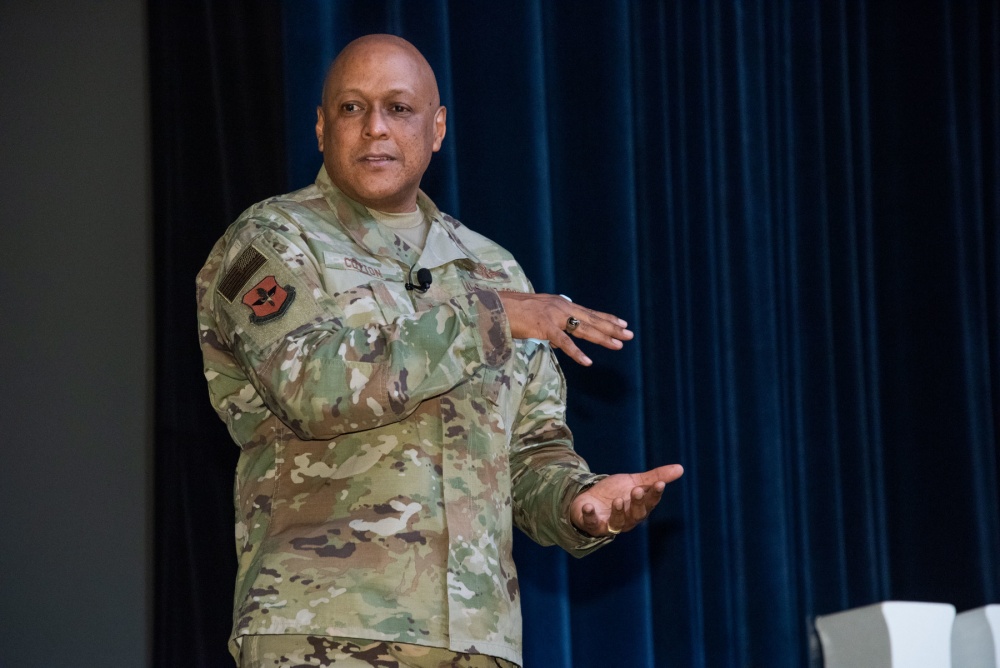

Lt. Gen. Alexus G. Grynkewich, the commander of Air Forces Central, said the move is an overdue recognition that coalition partners are an integral part of AFCENT.

“We’ve got a group of people that have been working together on various missions for 30 years, and we don’t actually have something that we can all say is our patch, where we’re working together,” Grynkewich told Air & Space Forces Magazine. “And so that’s what we’ve tried to create.”

Military patches can carry significance, whether it is showing pride in serving with a specific unit or showcasing joint commands.

This one is largely green, a color long associated with Islam, with a burst of yellow representing the sun and desert and a blue star, the historical Air Force symbol.

For AFCENT, the process of getting a new patch approved in a bureaucratic organization like the U.S. military was surprisingly easy. The command went to Air Force’s heraldry department, which is responsible for patches and the processes, and encountered only a few hurdles.

Grynkewich said the design was centered around being “historically significant and culturally appropriate.”

As the U.S. military footprint in the Middle East has shrunk in recent years, building partnerships has become an increasing important element of CENTCOM’s strategy. That has put a premium on getting Arab members of the coalition to work together and encourage military cooperation with Israel, which in 2021 was shifted from the U.S. European Command area of responsibly to CENTCOM’s.

Airmen in the Middle East already carry a number of hats. Officially, AFCENT is the 9th Air Force, tracing its lineage back to a World War II unit that fought in Europe and North Africa as part to the Army Air Forces. Members of the command have worn both Air Forces Central and Ninth Air Force patches.

AFCENT’s new patch, in contrast, recognizes the 18 countries that all work together in the Combined Air Operations Center at Al Udeid Air Base, Qatar, whose personnel can wear the patch.

“As we’ve transformed this command to focus on the long term, and on campaigning, in addition to being able to run day-to-day combat operations, we’re really trying to expand that coalition presence across the entire headquarters,” Grynkewich said. “The intent would be it was something that any of the coalition partners including the U.S. could wear on their uniforms.”

There are practical limitations: there is only so much space on a someone’s arm. AFCENT hopes to eventually create one patch to represent the 9th Air Force, Air Forces Central, and coalition partners.

“As you think about how you integrate those partners better into all of your different processes and into what your activities are in the region, it just becomes kind of a natural evolution that our minds all shifted to, oh boy, you know, we’ve actually got something here that’s pretty powerful,” Grynkewich said.