The certification of new aircraft programs is expensive. Whether it is an advanced air mobility system, a (hybrid-) electric aircraft or a military aircraft with new weapon systems, new and innovative aircraft programs are very complex. The application of new materials, additive-manufactured structures, electrical propulsion systems and an increase in onboard software requires extensive virtual and physical testing to verify whether the aircraft is safe, reliable and cost-effective to fly.

Managing verification from the start of the program, as soon as the requirements have been defined and validated, is a good practice. As the verification job is huge, especially for start-up programs, a digital verification management platform can significantly reduce the risk and related over-budget costs of aircraft certification.

Challenge – Aircraft Complexity

There’s a reason why airplanes are the safest mode of transportation: certification. For aerospace manufacturers, aircraft certification is everything. No certificate means no product to market.

In addition to already strict EASA, FAA, and other regulations, companies face additional demands for advancements, including – but not limited to – sustainability targets and the ambition to fly autonomously, which require more integrated systems driven by software and electronics.

New technologies like this are exponentially complex. They impact all aspects of product development, including design, validation, and testing. Instead of a few components and hundreds of interfaces, there are now thousands of components with tens of thousands of interfaces. More and more functions are implemented through software.

Implications – Aircraft Programs at Risk

Therefore, it’s no surprise that today, aircraft certification is more costly than design. This is a huge challenge. Many companies have great ambitions with new aircraft configurations. It is now technologically and financially feasible to build and fly prototypes and validate concepts. The big financial challenge and risks that a company faces are the costs of aircraft certification and industrialization. Indeed, Porsche Consulting estimated in 2018 that the series development and type certification of an eVTOL urban air mobility aircraft would cost between $500 million and $1 billion1, and Archer Aviation CEO Adam Goldstein says, “the price-tag for one aircraft design to reach certification could be up to $1 billion”.2

This represents a serious risk to many companies. As an aeronautical engineer, I cannot be more delighted when I see all the initiatives taken to exploit the possibilities of new propulsion systems into radical new aircraft configurations. In that sense, the last 5 to 10 years are comparable to the 1950s, when a lot of new aircraft configurations were explored. However, I’m worried that many companies with exciting new ideas will financially fail before getting aircraft certification.

One should not forget that many of these companies have to build the elements for proof of compliance from a blank sheet. They cannot count on data from previous programs to alleviate the verification process by comparison. This puts them at a competitive disadvantage against legacy companies, which might be less innovative but have an abundance of verification data at hand.

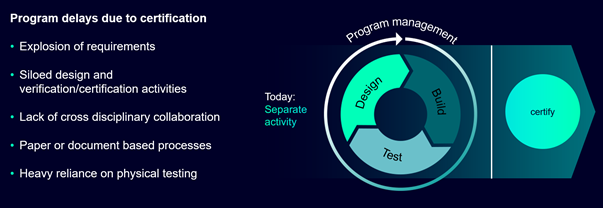

Because of the above, new organizations tend to postpone addressing the verification and certification aspects.

Opportunity – Certify During Development

Digitalization environments offer a lot of capabilities to pre-empt the aircraft certification aspects and associated risks.

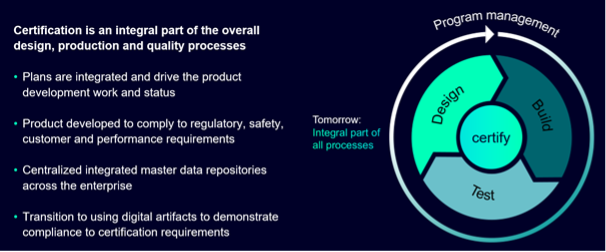

Process-wise, companies should consider including the verification and certification process within the aircraft design, development production and quality process from the start of the program.

Different digital platform pillars are key in this:

It Starts with the Digital Twin

Throughout the development of aircraft, digital twin capabilities make it possible to design, engineer and optimize the aircraft and its systems. They provide engineering insight into how the aircraft is built and how it performs behaviorally. The use of a digital twin model enables manufacturers to become exponentially more accurate in all aircraft domains, covering all “engineering physics,” which define how well it operates.

Given good management and validation of the modeling assumptions, these digital twin models can be further exploited to verify the behavior of electro-mechanical systems, coupled to the software-based control functions. Indeed, once one gets confidence in how well the models represent reality, these models can be used to perform virtual testing and alleviate the burden and costs of physical testing.

The ability to author these virtual test models is dependent on having the necessary skill tools for generating the engineering analysis data.

An additional benefit of digital twin models is that they not only help with accelerating the verification based on virtual testing, but they also have an under-recognized value in preparing and de-risking the physical tests, which will be needed anyway.

Indeed, as long as innovation continues to occur in this industry, it will be necessary for companies to prove the accuracy of their modeling assumptions, methods, and processes to aircraft certification authorities and organizations.

Digital twin technology is essential when programs want to reduce the risks related to aircraft certification. However, there is a closed-loop process needed between virtual and physical testing in order to make this a viable strategy.

Digital Data and Process Backbone

The amount of engineering analysis data a digital twin generates is enormous and requires a digital data and process management backbone to control it, keep it in configuration, manage the processes and make sure all data is traceable.

This backbone is also very important for the next programs. Indeed, stored data does not only serve current programs, but also can be reused in future programs to avoid verifying aspects multiple times on different programs. This drastically reduces verification costs of future programs, whether by simply re-using data or proving digital twin modeling assumptions were right and avoids physical verification on these aspects on the next program.

Digital Thread

The generation of engineering data using digital twin technology along with excellent data management is a start, but to be truly effective, the digital platform needs to keep all data generated and managed in the context of the aircraft program, as it assures the digital continuity of engineering data with the engineering decisions taken. As part of a model-based systems engineering (MBSE) approach, a verification management digital thread can provide a traceable link between the requirements and the artifacts that lead to the proof of compliance of that requirement, including all its intermediate data like the eBOM, test-BOM, etc.

Solution – Verification Management

A verification management digital thread should be a vital part of the digitalization strategy of all aerospace and/or defense companies. It can help make certification an integral part of the overall product development process and enable companies to have a robust certification execution plan and incorporates all the needed certification activities within the overall program plan.

It is vital that companies embrace not only a verification management digital thread, but also a full digitalization strategy. Digitalization enables aerospace manufacturers and their supply chain partners to make better-informed decisions based on extensive data and analysis as well as full traceability. It is the only way to turn the increased level of complexity and integration inherent in new programs into a competitive advantage.

The aerospace and defense industry is going through a time of immense innovation, and I’m excited to see what the future holds as A&D companies and teams of all sizes adopt digitalization to deliver on the promise of this innovation.

References

1. The Future of Vertical Mobility, Sizing the market for passenger, inspection, and goods services until 2035, A Porsche Consulting study, 2018

2. Can UAM developers turn their electric dreams into a reality? Pilar Wolfsteller, 2022

About the Author

Thierry Olbrechts is the Director of Simcenter Aerospace Industries Solutions, Siemens Digital Industries Software. In 1996, he joined Siemens Digital Industries Software. Since 2000, Thierry has been responsible for Siemens simulation and test business development and go-to-market strategies for the aviation, space and defense industry segments.