The U.S. has a lead over China and Russia in military propulsion, but there’s a real peril of losing that edge soon if research is not sustained and new engine technologies are not actually fielded, experts said at AFA’s Air, Space and Cyber conference last week. They also said that an engine “ecosystem” for Collaborative Combat Aircraft is still in its infancy, but chances are there will be no one-size-fits-all powerplant solution for CCA engines.

The Adaptive Engine Transition Program was “the last, big, major research and development activity” in the field of propulsion, said Michael R. Gregg, head of the Air Force Research Laboratory’s aerospace systems directorate, during a panel discussion, but that program dates back two decades.

The Pentagon also opted not to use either of the AETP engines in the F-35 Block 4 upgrade, and not seeing that work come to fruition is discouraging to potential propulsion engineers, Gregg said.

“If there isn’t a sustained effort” that continues to fund, develop, and field advanced engine technology, “industry is not going to keep talent in that pool,” Gregg said. The demand signal for engineers who can do such work “has really shrunk,” he added, as there is also no learning to be had from having an engine in the lab, but which has not been exposed to the rigors of real-world operation.

Meanwhile, military propulsion efforts are being stretched with more and more different demands in the fields of hypersonics, fighter engine technology, small engines for drones, and missiles, without a corresponding increase in funding.

“From a research perspective, we’re getting much more demand for the smaller engines,” which are “less exquisite, but maybe cheaper,” Gregg said. These efforts are coming at the expense of “that high-end, most exquisite, most technologically challenging,” engine work.

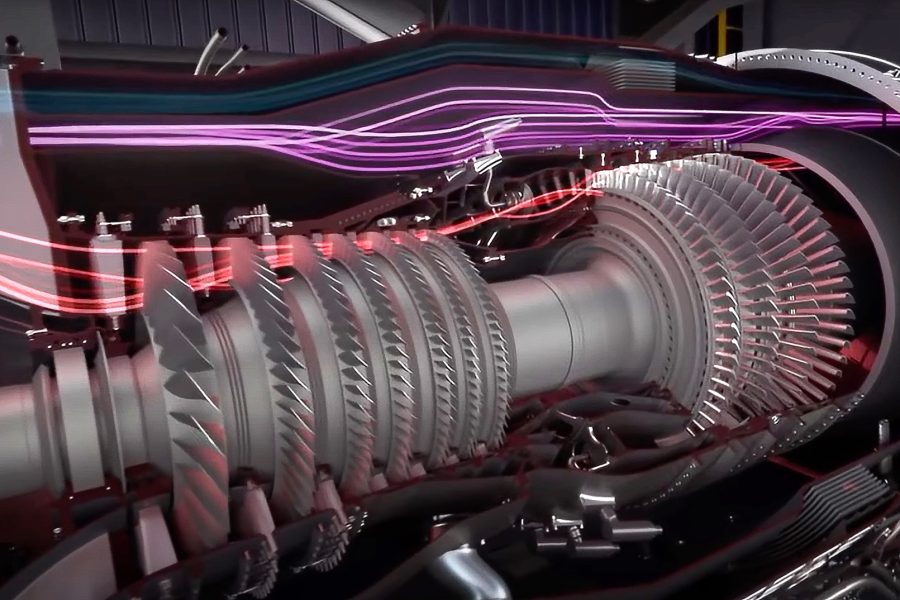

Advanced Engines

Experts have frequently noted that in a potential conflict in the Indo-Pacific or Europe, the U.S. would be fighting an “away game” against the likes of China and Russia.

“our adversary is going to have most likely strength in numbers, and they’ll have the benefit of proximity. What they don’t have today is an advantage in propulsion capability, but they are working hard to close those gaps,” said David Tweedie, GE Aerospace Edison Works vice president and general manager for advanced products.

To maintain that edge, Tweedie called for steady, sustained investment.

In the AETP program, GE Aerospace built the XA100 and Pratt & Whiteny built the XA101, but the Pentagon opted not to use either one for the F-35. The knowledge gained from inventing adaptive engine technology won’t be lost; both companies are tweaking it for the Next-Generation Adaptive Propulsion (NGAP) program to power the Air Force’s next fighter. But the Next-Generation Air Dominance (NGAD) program is under review and will likely change. Senior leaders at the conference said they are contemplating a single-engine version of the NGAD, of which fewer than 300 are likely to be built. That may weigh against carrying two contractors into production.

While there is uncertainty around NGAD, though, Tweedie expressed confidence that the Air Force will always “need to put some sort of tactical platforms into a stand-in capability—crewed or uncrewed—with significant range, payload and survivability, and you’re going to need the next generation of propulsion system to make that work.”

Whenever that next generation is required, “we need to be ready, collectively, as an industry,” he concluded.

The ability to produce a cutting-edge fighter engine “doesn’t happen by accident,” Gregg said. “It takes sustained, persistent investment over a long time and right now, with the pace of aircraft [fielding] getting longer we have fewer in production, and we have fewer opportunities to bring in new systems.”

New technologies and digital tools are improving the propulsion engineering process, he added. But funding is needed to keep progress going and actually field new engines.

CCA

Another major challenge facing military propulsion is how to power the Air Force’s Collaborative Combat Aircraft—autonomous “wingmen” drones that need to be inexpensive but still reliable, yielding a capability that can keep up with fighters

Gregg said AFRL has not yet “cracked the code” on developing powerplants for CCA—and the process is made even harder by the fact that different CCA drones may have different missions.

“It would be nice if we could build an ecosystem” where engines are variable enough to be tailored to the mission, Gregg said. “We’re thinking hard about that. I think what drives CCA is ultimately going to be the price point. We want to think about maybe 1,000 to 5,000 hours of engine [life]. And if you think along those lines from the beginning, does that change your materials? Does that change your maintenance concept or sustainment concept? Does that change how you run it? So there’s lots of things that we need to experiment with, and learn and test and figure out, but from my point of view, CCA … really opens the aperture.”

Tweedie noted that GE inked a deal with Kratos Defense and Security over the summer to partner on smaller engines optimized for CCAs. Kratos “has a great skill set when it comes to agile, low-cost” engines, he said.

Pratt & Whitney vice president for military development program Chris Flynn predicted the Air Force will put a premium on speed in the CCA program—“I’ve got to go fast, right?”—and affordability.

“That’s where commercial-off-the-shelf comes in. We have a stable of engines at Pratt & Whitney that can provide various levels of thrust that can be pulled off of a production line today and inserted into a [CCA]. So that’s going to take care of the speed element,” Flynn said.

He noted that the Northrop Grumman Scaled Composites Model 437—an aircraft expected to experiment with CCA technologies—recently flew with a Pratt 535 engine.

“My prediction,” he added, “is that the Air Force is going to want more out of CCAs, not less.” They will need “more power and thermal capability” because they will be using artificial intelligence which will be “sucking all kinds of power, [and] they need cooling.”

Other Challenges

Tweedie said the biggest near-term challenge in propulsion is not just adding more power to aircraft but also to “deal with all those systems that generate heat.” With fighters loaded up with more and more processors, they generate lots of heat that must be dissipated, while the engines themselves must be cooler to reduce vulnerability to heat-tracking systems.

There are three ways to address the problem, he said: “First at the architectural level … adaptive engines provide a lot more levers for us to do some segregation between the thrust producing parts of the engine and the thermal and power sides of the engine, so you can get the best of both worlds.”

At the component level, “heat exchangers are critical to that lightweight, informal, complex geometry really lends itself to additive technology” and will “unlock the design engineers’ toolkit to be able to produce those.”

Third, he said, is integrating with the “multiple companies with different pieces” of an aircraft. They must avoid working in silos, he said. Digital tools especially help with that cross-communication.

Flynn said he sees “exponential increases in the requirements” for engine performance and cooling with sixth-generation aircraft. “And … it’s all about how we digitally design the system architecture.”

Thanks to the NGAP program’s digital foundation, “the propulsion enterprise is transforming” the way engines are designed, Flynn said, “in terms of being able to model these systems from end to end, quickly, identify what works and what doesn’t work, model that again and do this in a digital environment until you find the right solution.”

Tweedie also cited the shift from “nickel-based super-alloys in our hot sections, combustors and turbines” to ceramic-based materials as a major advancement, allowing the engines to run hotter and provide far more performance, while also being lighter. This was a case where the technology started out in military programs, was proved in commercial programs and led to advances on the XA100 and NGAP.

Flynn said Pratt has learned that “no matter what we do with specifying the way” an engine will be used, “when it gets to the field, it’s going to be used differently.” He said the company has formalized ways of feeding field experience back to the lab for a perpetual improvement program that “brings that learning back into our systems.”