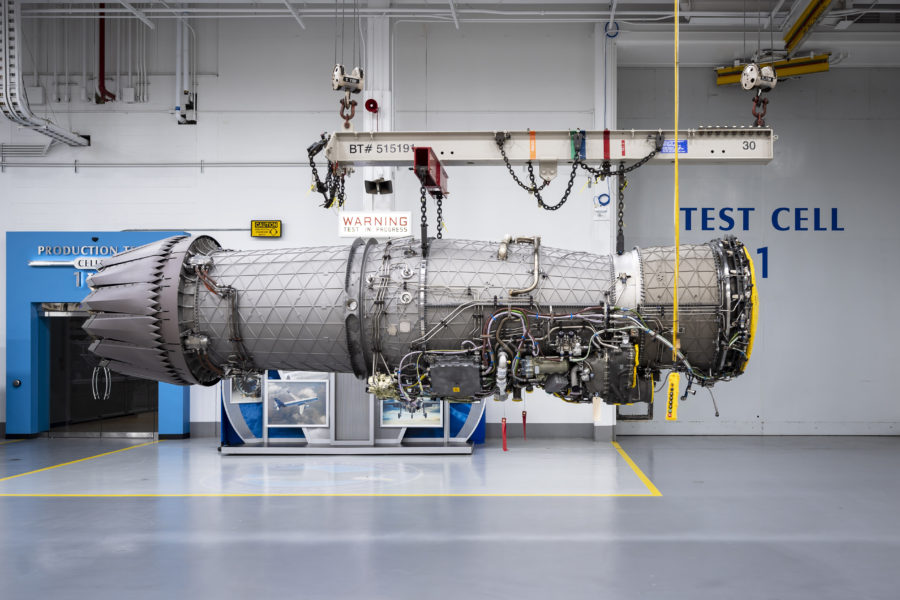

Pratt & Whitney and the F-35 Joint Program Office have completed the preliminary design review of the Engine Core Upgrade of the fighter’s F135 engine, the company said this week, adding that the ECU is “on schedule and exceeding expectations.” Pratt is a subsidiary of RTX.

The review “was a successful first step toward the capability the ECU will provide in meeting the challenging performance and durability requirements of the F135,” F-35 propulsion program manager Navy Capt. Mitchell Grant said in a press release. The ECU will “ensure that the U.S. and our international partners remain well-positioned to outpace adversary threats,” he added.

The Engine Core Upgrade will give the F-135 “increased capability and performance,” Pratt F135 vice president Chris Johnson said.

Critical design review is anticipated to take place in mid-2025, and the upgraded engine is supposed to be ready for fleet use in 2029.

The 2024 defense appropriations bill included $497 million to do detailed design work on the ECU.

The ECU was the propulsion choice made by the Pentagon after a long debate about whether to pursue more powerful Adaptive Engine Transition Program (AETP) engines developed by Pratt and GE Aerospace. Because the AETP engine was designed for the Air Force’s F-35A variant, that service would have had to bear the development cost alone, and Secretary Frank Kendall said in March 2023 that USAF couldn’t afford a unique engine. It was “the right decision,” Kendall said at the time, but one he said he’d like “another shot at,” given the advances the AETP engine would have offered in thrust and range.

An ECU would still have been necessary for other users of the F-35, and if the Air Force had pursued an AETP engine, two logistics trains would have been required to support the powerplants, which would not have much in common. “Commonality” has been the watchword of the F-35 since the program’s inception, and any user requiring unique equipment, software, or sustainment has to “pay to be different.”

Besides cost, the main attraction of the ECU is its compatibility with all three variants of the F-35. Either of the AETP engines would have required extensive new engineering and development to make them work with the short takeoff /vertical landing F-35B and carrier-capable F-35C.

Instead, the AETP technologies are being carrier over to the Next-Generation Adaptive Propulsion (NGAP) engine which will power the Next-Generation Air Dominance platform. Both Pratt and GE Aerospace are again working on that program. The NGAD will use a smaller engine than the F135, so a direct transfer of that powerplant won’t work with it.

The ECU is needed because the F-35 Block 4 upgrade will require more power for electronic warfare and to run the improved fighter’s more powerful processors. But it will also need more cooling capability, because the upgraded electronics will run hotter than on previous F-35 models.

To that end, the Joint Program Office is likely to release a request for proposals in the near future for a new Power and Thermal Management System. Government sources said that after long discussions with industry—notably with Honeywell, which makes the existing thermal management system, and Collins, which has developed an Enhanced Power and Cooling System (EPACS) for the F135 at its own expense—the JPO will probably pursue a competition for a new cooling system. The expense of a competition would be justified by reducing wear-and-tear on the F135 engines and getting more service life out of them.