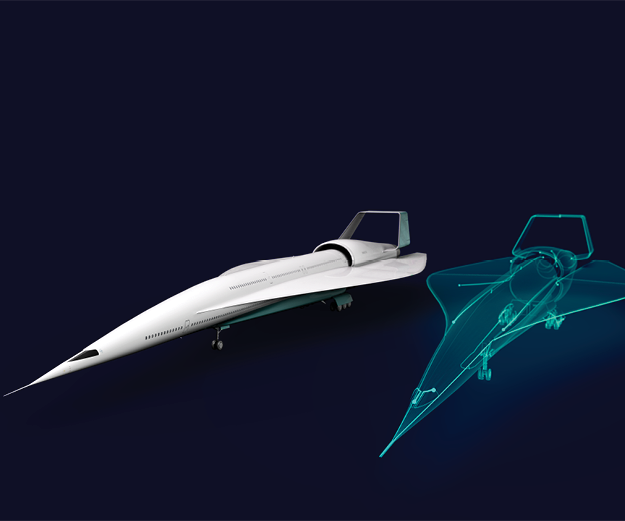

Since its inception, the digital twin has proven to be a revolutionary design tool for the aerospace and defense (A&D) industry. The ability to develop and test new products using virtual models (digital twins) before producing them physically has saved companies valuable time and money. Digital twins are used throughout the program lifecycle and have reduced engineers’ reliance on physical prototypes. Yet when can we stop building prototypes altogether?

There are still multiple obstacles in the A&D industry that prevent the comprehensive digital twin from replacing physical prototypes. These obstacles can be narrowed down to culture, processes, and technology.

To begin, imagine hearing on your next commercial flight, “Welcome to Autonomous Airways. This is our inaugural pilotless flight.” Then you hear the pilot’s welcome message from a voice that sounds like your iPhone. Most of us would unbuckle our seat belts and leave the plane.

The technology to enable pilotless commercial flight already exists, but it is not yet certified, and more importantly, it is not yet culturally acceptable. Ninety percent of your last commercial flight was already flown by a computer, but we all feel much better knowing that a real human pilot is there to take over if the computer makes a mistake.

We as people will need to build confidence in autonomous aircraft in careful, methodological steps. Building confidence in the comprehensive digital twin to replace physical prototypes will be no different. Engineers, program leaders, and regulatory agencies will need to learn to accept digital twins as prototypes, starting with less complex systems like circuit boards and landing gear struts, gradually scaling up toward full aircraft models.

This will require a change in our processes relating to prototypes and digital twins. Presently, engineers build a digital twin to model what they expect from physical hardware. These digital twins have enabled a “fly it before you build it mindset” Next, they build and test a physical prototype of said hardware and use the data gathered from those tests to validate their digital twin. This type of process sees truth in the physical piece, not the digital twin. To replace physical prototypes, engineers, program leaders, and regulatory agencies need to believe that the digital twin is the truth, eventually circumventing the need for validation testing with real hardware.

Engineers already have tools and software to virtually replicate complex systems. However, the integration of these simulated systems must continue to improve. Add this integration to seamless, out of the box simulation, with the right fidelity, running in real time, and confidence in digital twin performance will significantly increase. Continually validating and optimizing these digital twins with data and insights from physical test will eventually provide the fidelity and confidence needed to enable modeling and validation of very complex systems that have yet to be built in the physical world.

Replacing physical prototypes with digital twins requires visionary leaders throughout our industry who believe it can be done, who can inspire their companies to believe in it, too. Obstructions in culture, processes, and technology may prevent it now, but they will be overcome in time, and physical prototypes will go the way of slide rules and 8-track tapes.

About the Author:

Todd Tuthill is the Vice President for Aerospace and Defense at Siemens Digital Industries Software. He joined Siemens in June of 2022 after more than 30 years in the Aerospace and Defense industry. His engineering background is in systems design with functional engineering and program leadership roles and a strong vision for digital transformation.

Tuthill’s aerospace leadership career spans McDonnell Douglas/Boeing, Moog, Raytheon and Siemens, and his experience encompasses all aspects of A&D programs, including design, model-based systems engineering, software engineering, lean product development, supplier/partner management and program management. In his new role at Siemens, Tuthill is a passionate advocate for the advancement of digital transformation across the A&D Industry.