Pratt & Whitney’s F100 engine debuted in 1972 and continues to power F-15 and F-16 jets for the U.S. Air Force and allied militaries around the globe. Josh Goodman, who leads the F100 program at Pratt & Whitney, and Nick “JDAM” Graham, a former U.S. Air Force F-15 Weapon Systems Officer and now senior manager in the company’s F100 program office, share what the engine has achieved so far—and what comes next.

What is it about the F100 engine that makes it unique?

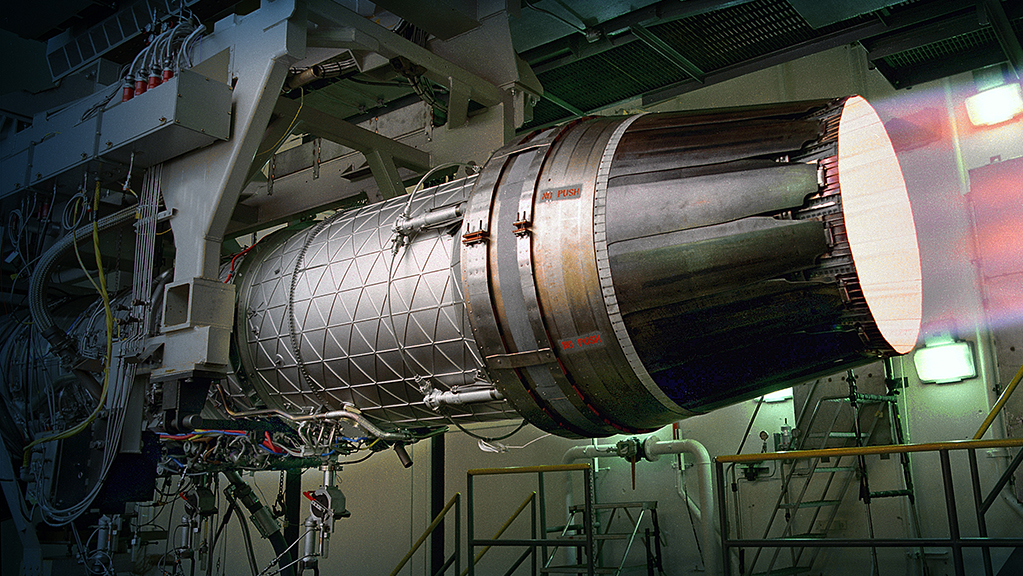

Josh Goodman: The F100 is the engine that powers the F-15, the F-16, and more recently, provides the gas turbine core capability in the Quarterhorse and Darkhorse uncrewed platforms under development by Hermeus. The F100 flew on the first flight of the F-15 in 1972, and earlier this year, we celebrated the 50th anniversary of the first flight of the F-16 in 1974. Since its debut, F100 engines have surpassed 30 million flight hours—nearly three times as many hours as other fourth-generation fighter engines.

The F100 has an unmatched record of safety and reliability: According to the Air Force Safety Center, it is the safest fourth-generation engine in a single-engine fighter application. For the U.S. Air Force, the engine currently meets its aggressive mean time between removal requirement, which increased in 2020 because of its consistent performance. We have a superior thrust-to-weight ratio. Feedback from pilots indicates that the pilot-throttle response is unmatched, which gives the Thunderbird pilots the ability to put their wingtips mere inches from each other.

The F100 has a modular design, and our sustainment approach at Pratt & Whitney is part of the engine’s value proposition in the marketplace.

Pratt & Whitney F100-powered F-15s and F-16s have an undefeated combat record, 165 to 0 — a little bit of an aged statistic, just prior to some of the more recent conflicts that the F100 is fighting in the world. We’re the only fourth-generation engine that provides operationally proven fifth-generation technologies, such as thermal coatings, improved turbine cooling capabilities, and prognostics.

Moving forward, we have the ability to grow thrust. We have additional bleed and horsepower extraction capabilities to give back to the aircraft. In short, the F100s coming off our active production line have been modernized and they are a technically superior product that enables expanded airframe capability. The Pratt & Whitney F100 truly remains the very best choice for the F-15 and F-16 (including the latest variants like the F-15EX and F-16 block 72).

Nick Graham: During my time in the Air Force flying the F-15E, I flew over 1,000 hours of combat sorties in Iraq and Afghanistan—220 combat missions in all—and every single one of those was flying the F100 engine. There are so many things we need to consider and concern ourselves with in combat: whether troops are taking fire on the ground; [if] it’s night; if you have to dive down under the weather in Afghanistan in between the mountains to try to pick out targets — lots of details competing for attention. The one thing I never had to worry about were the two engines powering my aircraft.

You mentioned the potential for more thrust. What difference might that make for pilots?

JG: Integrating additional electronics requires additional cooling potential for the aircraft. That requires additional bleed from the engine, or alternative means, but given the engine’s capability, we have the ability to provide that cooling potential to enable the aircraft to add mission capability. By decreasing the weight, it gives you the ability to load out additional capabilities on the aircraft.

NG: The aircraft that the F100 powers currently all have a prominent air-to-ground role. When it comes to the value of these aircraft in combat scenarios, being able to fly further with more ordnance is an incredibly high value. You always have to concern yourself with your weight: How much can you hook on the aircraft? How far can you go with it efficiently? From my experience flying the F-15E model, we put a lot of weapons on that aircraft. The ground commanders, the combatant commanders, love to call on that aircraft because they know they’re getting a lot of bang when we show up. Any way we can reduce weight in the aircraft to allow us to either put more ordnance on there or, at a lower weight, we fly a little bit further and hang around a little bit longer … is beneficial to everybody.

What other platforms do you envision for the F100?

JG: There’s been some press recently on taking the F-15 to an electronic warfare version. That will require exactly what we’re talking about: additional electronics for that mission, and we’ve got to figure out how to power and cool them and how to afford the added weight. Stepping a little bit outside of the traditional F-15 and F-16 applications … the Hermeus aircraft gives you another example of the F100’s capability. The Hermeus organization is seeking a low-risk solution to get into the Mach 2, Mach 3 range until they cocoon the engine and engage the ramjet portion of the combined cycle propulsion system to get to approximately Mach 5. The history, the safety and the people that stand behind this engine all play into its reliability, that low risk, and the reason that it is a chosen solution for future nontraditional applications beyond F-15s and F-16s.

What unique considerations do you have to work through when adding the F100 to a new platform?

JG: There is a very rigorous qualification program to ensure that the aircraft-engine interface — all the wires and/or cables that exist — are connected properly and responding properly to ensure that we’re keeping our brave men and women safe. We like when the number of landings equals the number of takeoffs, and we want to keep it that way.

What’s unique about including the F100 in a hypersonic propulsion system for Hermeus?

JG: The engine that will go into the combined-cycle propulsion system for Hermeus is not the same engine that powers F-15s and F-16s. It is very, very similar. But there are differences in hardware—and particularly in software—in integrating the majority of the F100 into the combined-cycle propulsion system. However, because we’re keeping most of the engine common, we get to take advantage of the stellar record of reliability and safety in that application.

What improvements do pilots and maintainers tell you they’d like to see in the F100?

NG: From the fliers’ perspective, range is always first. As adversaries get better systems, we all end up pushing further and further away from each other by design. Engines that can deliver the range to give us the advantage are always in need. The thrust-to-weight ratio of our engines certainly helps with that. … And there’s some opportunity for growth in that area. When it comes to modern air combat, the electromagnetic spectrum and directed energy weapons that may come down the line in the future all require power. We have a tremendous growth capacity that already exists in our F100-PW-229 engines to provide excess power to customers who want to install additional systems on those aircraft. So as we step forward into more transmitters — more power being transmitted from the aircraft — our engines have the capability to do a lot more than they are doing today.

JG: At the component level, we are continually learning from our designs on our fifth- and sixth-gen engines and seeking the opportunity to integrate those technologies back into our fourth-generation engines. We look at this modernization not only from a system perspective, but at a component-level perspective as well, to ensure that we are continually improving the value of this engine to the warfighter.

At the end of the day, Pratt & Whitney likes to do hard things. That’s why we’re in this business.

How would you describe the state of the F100 sustainment enterprise right now?

JG: We have 23 air forces, including the U.S. Air Force that we support worldwide. It creates a rather dynamic environment.

The great thing about the F100 organization within Pratt & Whitney is that we meet a customer’s sustainment demands in whatever way they want. Where we have a more integrated, strategic [performance-based logistics]-type relationship, we absolutely see the best affordability and availability, because all our incentives are aligned. But we also have the ability to support from a transactional perspective. We have invested in digital tools to help us better understand exactly what’s going on in the world and how we can optimize. Sustainment is about affordability and availability, and we have plans in the future to engage additional machine learning, AI capabilities in order to further improve that support. Most of our AI exploration so far has been on the supply side of the analysis. We are currently in the process of expanding that to the demand side of the analysis. This is all about optimizing support worldwide for our customers.

You’re now delivering F100s to Poland. What have you done to ramp up that production line, and do you expect it to keep growing?

JG: The F100 production line has been and is active. We’re delivering actively for both aircraft and spares to worldwide customers. Because we believe the F100 remains the best choice, we absolutely are continuing to pursue not only traditional F-15 and F-16 offerings (including the latest variants like F-15EX and F-16 block 72) but also the non-traditional ones like Hermeus.

What upgrades are on the horizon that you’re under contract for or that you’re going for right now? What could we expect to see in the next five years?

JG: We’ve put together modernization packages at the system level that showcase capability expansion. It’s less about thrust, and more about horsepower extraction and bleeds. We’re actively in conversation with our customers in order to engage those capabilities for the warfighter.

What role do you see for the F100 in engine modernization efforts going forward?

JG: We’re going to continue to modernize the engine both at the component and system levels. At the component level, making it safer and more reliable; at the system level, providing additional capability to the aircraft and the warfighter. We’re going to continue to actively promote the Hermeus relationship for its one-of-a-kind solution, and we’re going to continue to seek these non-traditional applications where a low-risk engine like the F100 presents an advantage—even in a futuristic-type application like Hermeus. For drones that are in the thrust class, we expect to see the opportunity for F100 to fill that need, as well.

Is there anything else that we should know?

JG: Outstanding past, exceptional future. We’re really excited about supporting this engine for another 50 years and to continue adding new engines into the field and ensuring that the company, processes, and global infrastructure exist to support this engine across the world.

NG: We have 50 years of history on this engine and it’s going to be powering aircraft for a long time. We’re ready to support that as far as we can into the future. In all the combat time I’ve had, I’ve had to adjust and cancel combat sorties for pretty much every system on the aircraft—weapons, sensors, hydraulics, you name it. But in my 220 combat sorties, I never once had to cancel or alter a combat sortie due to engines. When we talk about reliability, these engines got me where my pilot and I needed to go to provide support to our forces on the ground. And they did it 100 percent of the time.

JG: The Pratt & Whitney F100 has had an incredible and iconic history, but at P&W, we are most excited about its future: the F100s coming off our active production line have been modernized and they are a technically superior product that enables expanded airframe capability. The Pratt & Whitney F100 truly remains the very best choice for the F-15 and F-16 (including the latest variants like the F-15EX and F-16 block 72).